GruppeM: carbon fiber dreams

- Samuel Parra

Maybe GruppeM is not a familiar name for some of you, but in our last trip to Japan, it was one of the places I was more eager to visit.

Its founder, Mr. Mamoru Ogose, has always been someone to look up to for me since I first heard of him. A self-made man who decided to create his own business when he found out that what he wanted didn’t exist. That’s how GruppeM was born in 1996, with the intention of creating the best carbon fiber intake systems that money could buy.

21 years later, and with only 20 people working in the company, they’re not only still in the business, but have also

expanded further, being the only official distributor for K&N filters in Japan, working with brands such as Mazda,

Nismo or Mugen, also creating aerodynamic kits for various cars, exhaust systems, braided brake hoses and having

created a whole section devoted to racing which includes wheel designs and fabrication and race suits.

21 years later, and with only 20 people working in the company, they’re not only still in the business, but have also

expanded further, being the only official distributor for K&N filters in Japan, working with brands such as Mazda,

Nismo or Mugen, also creating aerodynamic kits for various cars, exhaust systems, braided brake hoses and having

created a whole section devoted to racing which includes wheel designs and fabrication and race suits.

Mamoru Ogose, second on the right, at GruppeM’s stand in Tokyo Auto Salon 2017.

Mamoru Ogose, second on the right, at GruppeM’s stand in Tokyo Auto Salon 2017.

However -and this is something that you realize as soon as you meet Mr. Ogose-, the main goal of GruppeM hasn’t changed a bit since the day they started doing business: to squeeze the very last drop out of the cars they modify by creating carbon fiber intake systems, designed by Mr. Ogose himself. Below you can find the whole interview we did with him.

StreetRunners: Thanks for being with us today. I really wanted to meet you, especially because I am using one of your intakes in my Mazda MX-5, and I really wanted to talk to one of the people that helped to create it.

Mamoru Ogose: Thanks, and welcome. First of all, let me say that I did not help to create the intake you’re using in your car. I designed it by myself. The same applies to all the intake systems we sell… I just happen to love cars. When I was young I really loved going fast in any kind of vehicle: first it was bikes, then motorbikes, and finally cars. I never liked stock, it has never been enough for me. That’s why GruppeM was born, because I was always looking for a way to make cars faster, more efficient, or even nicer under the hood. 30 years ago, when I started this business, car manufacturers didn’t know as much as they know today about how to squeeze more power from their engines, starting from the intake.

30 years ago I got a speed record in the Yatabe course of over 200 miles per hour with a Nissan Z which I had modified myself. It was then when I started getting lots of questions from everywhere: how could I reach those speeds? What kind of aerodynamic modifications was I using?

The answer was that I was using all my time to study by myself. I read magazines and technical books, I tried to understand how I could get more power out of an engine, and then I tried those things in my car. I ended up having a full custom intake system, also a custom exhaust system and an aerodynamic kit. It wasn’t very aggressive as I’m not into big wings and those kind of things: it was purely functional. One thing led to another one and, 30 years later, I’m still doing the same: my designs are purely efficient so I can get the best performance out of a car.

SR: What’s the process of creating a new intake system?

MO: We do everything in Japan. Our products are designed in this building, built in this building and tested in this facility. Some other companies outsource their fabrication to China, Taiwan or other countries, but the problem with that is that they skip the testing phase, so they don’t know if their product will be good enough until they receive the first units.

At GruppeM we build the first cast of the part we’re creating after roughly two weeks of designing it. We then build some test parts with that mold and test them in the car they’re designed for about two more weeks. So it takes us at least 6 weeks to have a production-ready part that we are happy with. However, if during testing we notice that we didn’t get the expected results, we have to start again from scratch, modifying the original design. Truth is, the 3D design tools that exist nowadays make it very different to create an aftermarket intake kit than it was 30 years ago, and this has helped us to be more efficient in our designs.

SR: Speaking about that, could you tell us how has the whole process of developing a kit like the ones you sell in these 30 years?

MO: There are lots of sensors and gauges everywhere now: temperature, flow, and so on. 30 years ago, you had to actually stick your head under the hood to see, listen and smell what was going on. Now you just check some tables with all the sensors data and you have all the information you need.

You should also take into account that 30 years ago, fuel injection systems didn’t exist. There were only carburetors: Weber, Solex… the way of properly tuning those systems was by ear, and visually checking that the engine wasn’t vibrating too much. Nowadays we have sensors placed everywhere, but back then we lived in an analog world and we couldn’t monitor any number to see what was going on.

The cars I tuned, I changed things based on what I heard and saw… and how it felt when I drove them. I could feel if was running rich or lean, and some people would say “Mr. Ogose, your tuning is the best!” but I didn’t have any real, technical knowledge of what I was doing. I just knew that it felt better when being driven.

Time went by and sensor prices started to go down. It was amazing, because when we used those to get some numbers, the correct tuning according to “the data” was quite close to the ones I had done before, and that’s when I understood why the cars just felt “right” when driving them.

How was I able to tune cars like that? I think I’m just crazy about performance. And that’s also the reason why I don’t want to stop doing what I’m doing. I still have that competitive spirit, I still want to win. Maybe that’s the reason why GruppeM is still in the business.

SR: Before creating GruppeM, you worked for RUF. How was the experience? And what were your first steps in the motorsports world?

MO: Well, cars have always been my hobby. I’m also very competitive, I have always wanted to win in everything I’ve taken part in, also in business. That’s why I joined RUF, who are quite different from Porsche.

In the 80s, RUF had the BTR and the CTR, cars which were much better than the Porsches they were based on. I was really interested in the RUF way of thinking: the base car was a Porsche, but RUF cars weren’t Porsches themselves. They had the same things I had always been attracted to: more power and aggressive and functional aerodynamics which still preserved the original 911 shape. I really liked that way of thinking. So I went to the RUF factory and told them I wanted to work for them. I did that for 3 years, and then I got to a point in which I said to myself “OK, you already understand enough of their way of working. Now you have to do something similar in Japan”. To this day I still love RUF. Maybe the new investors have changed a bit their philosophy, but, even today, a RUF is still a RUF.

So, as I was saying, I learned everything I could from RUF and some other companies, but my way of thinking stayed the same: a car must be both powerful and beautiful. That’s always been my motto. A car can have 1000 horsepower, but if it has wires hanging out in the cabin, or the welds don’t have a good finish… I’m not saying it’s a bad car, but…

Some could say “who cares about these things? What’s important is speed!”, but that’s not how I think. I think both things should go together.

SR: Once you came back to Japan, you started selling K&N air filters. Why did you decide to go one step further and sell complete intake kits made by you together with the air filters?

MO: Well, the beginnings of K&N filters distribution era in Japan make up for an interesting story. About 25 years ago I visited California as I had some matters to talk with RUF. While in there, I heard that a RUF CTR was racing in a nearby circuit, so I went there to check it out because nobody had a RUF in Japan back then, they only existed in Europe and America, and I wanted to see it with my own eyes.

Once I arrived at the circuit, I saw the RUF car, but I also saw that there was another Porsche racing which didn’t sound very good. By the sound it made, I knew that it was using a Weber carburetor. The driver did a few laps around the circuit, but it was obvious that the car didn’t run well. During one of those laps, the driver stopped right in front of me and started checking his engine. While he was doing that I approached him and asked: “why don’t you adjust the carburetor?”. He answered that he didn’t know how to do that, and that the car had just been tuned by his mechanic specifically for that circuit, and that the problem must have been in another place. I explained to him that I came from Japan and I loved Porsches and carburetors, and I asked him if I could adjust it myself. I asked for a screwdriver and I tuned it by ear, and then told him to do a few laps. He looked at me strangely and asked “Really? That’s all?” “Yes, it should be fine now, go test it”, I answered. As soon as I heard the car revving up I knew I had fixed the problem, as the sound was much better than before. So he stopped in front of me again and asked how had I been able to fix it with only a screwdriver. We kept on talking for a bit and he asked if I was living in the US, I said that I was just visiting but I developed automotive products in Japan. He said that his business also made great products and he invited me to visit him.

That man was K&N’s president. That’s how I got in contact with them, and they gave me the distribution rights to their products in Japan. I explained to them my intentions: I wanted to do high-end intake kits, and I wanted to use their filters in them. I told them “let’s do a ram air intake kit”, but they told me that the development costs would be too high and nobody would want to pay that much money for a car part. It was at that time that K&N changed their president, and I was asked to stop using the K&N Japan name, as they wanted to be seen as a 100% American company. So I decided to do the intake kits I wanted to do in my own company: GruppeM.

I talked to K&N once more and told them “I’m going to create the best intake kits in the world. Do you want to join?” Again, they said no. They were investigating some other stuff at that time and they weren’t interested, so I started this business by myself. As I still had a good relationship with them, I was allowed to use their filters in the kits we sell, and up to this day we still use them.

New generations at K&N now tell me “Mr. Ogose, why don’t you join us? Let’s do a K&N ram air intake kit!”. But that belongs to the past now. Both companies have followed different paths, and although we still are in good terms with each other, we work on different things now.

SR: Regarding the company name, GruppeM. Why not GruppeO (from Ogose, the family name?)

MO: The M in GruppeM stands for Mamoru, my name. Usually, Japanese people use their family name when creating businesses, but this one was built by me. If I had used the family name for its name, how would anybody know who created it? It could be my dad, my mom, my sister… I wanted to use my own name in my company.

SR: You have witnessed the evolution of car related businesses in the last 30 years. Where do you think they are heading now? What’s next?

MO: I think that car companies already have everything they need. They do everything in-house and they don’t need aftermarket as much as they did some years ago. My opinion is that we are heading towards an all-automatic world. Autonomous cars and the era of electronics. I don’t think the internal combustion engine will last much longer. As an example, the new NSX has an electric motor in it as an aid for the main engine. But I believe the next generation will only be sold with an electric motor.

Problem is that even today, designing intake kits for hybrid cars is difficult. If I create an intake kit which works well with the combustion engine, it won’t be good for the electric motor. A Prius, for example. The owner of that type of car wants the electric motor to be the one that’s providing the power, not the combustion engine. He wants it to be used as little as possible.

We’re not interested in those cars. No engine sound, no petrol smell… only tires. That’s why we started restoring classic cars around 5 years ago: Porsche, Ferrari… From what we’ve seen, we believe that car manufacturers don’t know how to restore a classic car the way it deserves. Even in the car dealership, they will try to convince you of getting rid of your old car and getting a new one instead of restoring it.

If you want a classic car for any reason, you don’t mind it being more difficult to drive, not having any assists or being noisier than a new car… What really matters is how it makes you feel. They’re like a good watch, or a jewel: you should be able to use them forever.

It’s true that we could do new intake systems, in fact, we still do for Mugen, Nismo and so. But the direction the industry is going is another one: easier to drive, and more horsepower. But for a price. 500 horsepower, for example. I think that’s a good number. But for a GT-R, which is so heavy, that’s not enough. 1000 horsepower in a GT-R would be ideal for my taste, but it would still be a heavyweight car.

Cars must be lightweight. In fact, they should be built taking into account lightness, power, and sound. And that’s exactly what you get when you drive a classic car.

SR: What was the best automotive era in your opinion? 80s? 90s?

MO: I believe it was the 70s. In that era, I had a lot of dreams, a lot of passion for everything I was doing. Around 1972 or 1973… Yes, I would say those were the best years for me. That’s the reason my cars are from that era. I have a 1972 911, another one from 1973… I also have a Datsun. I really love those years.

SR: And your favorite car from your personal collection?

MO: That’s a difficult one. I really like the 911, but on the other hand, I’ve had something like 7 or 8 Ferrari 355. I always ended up modifying them, especially on the inside. As I was saying before, I’m not really into aesthetic modifications that stand out a lot, but I always did something to their interiors: alcantara seats, some weight reduction… that’s the kind of design I like. I also design race suits, so I love drawing.

When the 355 came out around 1995, I fell in love with its design. But not with its interior. So I started drawing a lightweight alcantara seat with some nice stitching, and I kept on and on, creating an intake and an exhaust to match. What I did in the interior was like a factory lightweight version in a time in which Ferrari didn’t offer such option. They only had the Challenge version, in which pretty much all the interior was stripped. That wasn’t my idea, I liked street cars, but with some weight reduction. With the 360, Ferrari offered a Challenge Stradale version, which was very similar to what I had in mind when I designed my 355 interiors. Nowadays, lightweight versions are being sold with great success, and I find it funny that I did the same so many years ago: it’s not about stripping everything that’s not necessary but creating a lightweight version which still has the usual stuff that you find on a street car.

SR: Why did you decide to create a supercharger kit for the Honda NSX? I mean, for a company that was mainly designing intake kits at that time, why a supercharger? And why for the NSX?

MO: I really loved the shape of the NSX. I liked it so much that I bought it. When I drove it for the first time, I felt that it was lacking some power. However, everybody said “don’t touch anything on the engine! This is Honda’s most perfect engine. God himself did this car. Don’t change the suspension, don’t do anything to it. Everything that this car has is the best”. But I still thought the same thing when I drove it, it needed more power. I didn’t have fun driving it. “How could this car be built by God? For me, I am God (laughs). So let’s change some things about this car”.

Back in the 90s, nobody used superchargers. It was an original idea, and I wanted to try something new. As I already had some contacts in the USA and the American people loved superchargers, I went there and spoke to Eaton. When I explained to them what I was planning to do, they told me that I didn’t know what I was saying, that the NSX’s engine was high compression and that one could not simply attach a supercharger to it. I told them that I could build a better injection system, I could swap the ECU, I could replace the injectors… whatever was necessary.

So I left Eaton with one of their superchargers, and when I got back to Japan I designed some brackets to install the supercharger. I changed injectors, I changed the ECU, but I didn’t modify the compression. If the kit had been built exclusively for me, I could have done that too, but we wanted to create something which was easy to install. We built 100 kits, and we sold about 20 in Japan. The rest were sold in Europe and America. The truth is that, with the supercharger, the car became more fun to drive, with approximately 380hp, 100 more than in stock form. That may not look like a great improvement, but they were enough for a car like the NSX. I could have achieved bigger numbers with a turbocharger, but I created this kit with the intention of not shortening the life of the engine at all. The problem is that the engine of the NSX is not good for installing a turbo, both because of the amount of heat it generates and because of the available space in there. That’s why I chose a turbocharger.

Every product that we offer has a similar story to that one: they start as a personal hobby of mine. I want something, so I design it, and it turns out that our client also want something similar, so we put it on sale.

SR: One last question: when you design a new intake kit, you’re always aiming for better performance. But what else is taken into account? I mean, do you try to also improve the sound? Make it prettier under the hood?

MO: As you said, our main goal is performance. But I’d say it’s a mix of everything in the end. Of course, it must sound good, but it also has to be beautiful and functional. For example, 300 horsepower. I could get more power out of a car, but I’d rather stay at 300, be able to get them fast and use them through a large range of rpm. Why do I want 500 horsepower for, if I’m only going to be able to use them when close to the redline?

That’s my goal, and that’s why it is so difficult.

After this small interview to Mr. Ogose, he showed us around his factory, where we could see not only a big part of his catalog of carbon intakes (when we visited GruppeM they were getting ready for the Tokyo Auto Salon and had most of their stock ready to be displayed) but also how the steel brake lines were being made.

Apart from car parts, the latest adventure of GruppeM has been becoming the official japanese distributor of Zenos, an English company who builds sport cars, for which GruppeM has also created intake kits:

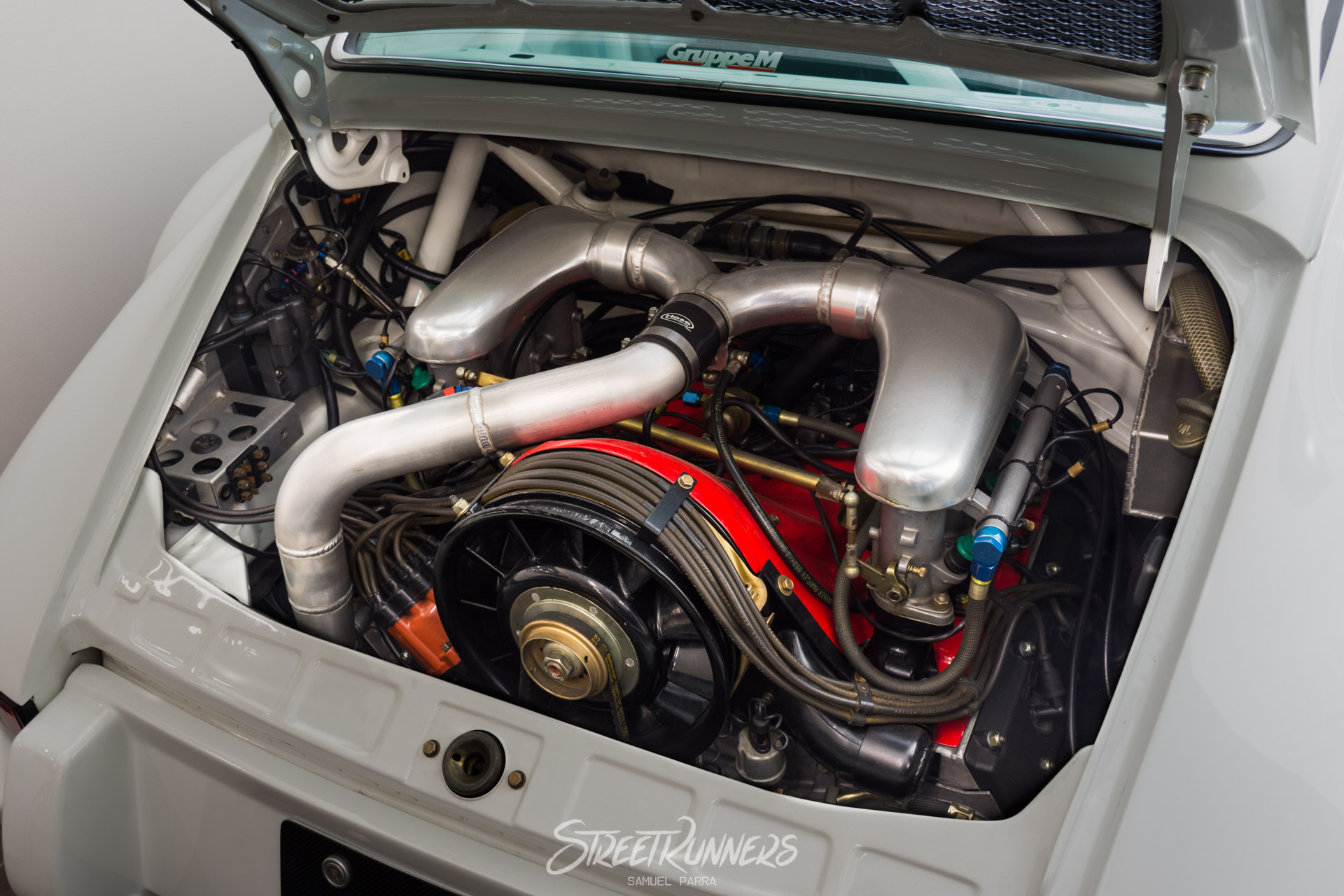

Before our visit came to an end, we also saw the classic cars restoration area, where a small portion of Mr. Ogose’s

Porsche collection was stored, all of them having been restored in-house. There were really incredible cars, but you’ll

have to trust us on this one as we weren’t allowed to take pictures of customers’ cars. What I did take pictures of

was a Datsun 240Z which was being restored to the point of even smelling like a factory new car.

Before our visit came to an end, we also saw the classic cars restoration area, where a small portion of Mr. Ogose’s

Porsche collection was stored, all of them having been restored in-house. There were really incredible cars, but you’ll

have to trust us on this one as we weren’t allowed to take pictures of customers’ cars. What I did take pictures of

was a Datsun 240Z which was being restored to the point of even smelling like a factory new car.

The truth is that we really enjoyed our visit and the opportunity of meeting one of the big names of the aftermarket scene in Japan. We would really like to thank Mr. Ogose and his team for their hospitality and their time, and we hope we can meet again soon.

By the way, when I asked him about the Mid Night Club and the 90s street racers, Mr. Ogose told us that he had been a street racer himself some years before the club was born, racing other cars at high speeds through the wangan in his blue Datsun 240Z which would later inspire quite a few legends…